How to Choose a Continuous Temperature Monitoring System

Owning or managing a restaurant requires scrupulous attention to detail. Your hospitality success depends on proactive awareness of every step of your operations, from ensuring the punctual delivery of produce to meeting clientele demands. Managing cold storage equipment can often fall by the wayside within such a high-touch and fast-moving context, leading to loss events or expensive emergency maintenance.

To automate refrigeration management, restaurateurs have turned to a new solution, continuous temperature monitoring systems. Currently, only 5% of restaurants use remote temperature systems to autonomously, consistently, and continuously monitor equipment temperatures and inventory conditions. However, not all sensors on the market are the best for restaurants’ unique needs, so it’s essential to understand the options before committing to a sensor system.

How do temperature monitoring systems work?

Sensor technology is as diverse as the users that implement it. When deciding on a temperature monitor system, you should evaluate carefully which type of sensor best suits your business, considering factors such as range, cost, reliability, installation, and scalability.

To simplify your research, here’s everything you need to know about temperature monitoring methods.

Manual temperature monitoring

The most common method of manual temperature monitoring is to use thermometers. These old pieces of equipment are a timeless favorite due to their accessibility and ease of use.

Thermometers function according to a simple design: they consist of a sealed glass tube labeled with marks that correlate to known temperatures. The tube contains a liquid—usually mercury. As the external temperature increases, the liquid expands and rises inside the tube revealing the current ambient temperature.

From there, a team member logs thermometer readings at scheduled intervals on a paper log. Sometimes that information is later transferred to a computer spreadsheet.

Thermometers can be positioned virtually anywhere with minimal installation time and no need to worry about networks or batteries. Additionally, your team can easily understand the data they provide. Thermometers are the cheapest and easiest way to monitor cold storage temperature, which is why they are a popular choice.

Unfortunately, manual thermometer readings are often incorrect. This can be due to:

- Improper calibration

- Human error in recording or interpreting data

- Changing environmental conditions

As a result, most thermometers lack the technological ability to solve these problems.

Logging thermometer data with pen and paper also leaves room for sloppy or forged record-keeping, also known as “pencil whipping.” This happens when employees record data and sign documents without proper evaluation. When pencil whipping occurs, owners and managers may never know that the temperature is incorrect. Therefore if a problem arises, there is no way of knowing when the problem started or how severe it is.

Wired temperature monitoring solutions

Wired sensors, or hardware embedded in the infrastructure of your cold storage, use physical connections to transmit information via Ethernet. These sensors were the first generation of digital continuous temperature monitors, providing significant benefits over manual and wired solutions. They tend to be sturdy and durable, and they do not depend on a WiFi connection to transmit data, rendering them functional in many locations.

There are a wide variety of wired sensors on the market. However, wired solutions are expensive to install depending on:

- The physical attributes of the area you want to monitor

- The number of sensors required

- The level of difficulty involved in installing the embedded wiring

It’s also difficult to change or update wired systems since the same initial installation difficulties apply to maintenance and scaling. The bigger your restaurant is, the more the installation will cost, making a return on investment difficult. Because of these installation drawbacks, wired sensors are not a viable option for some small businesses.

Wireless temperature monitoring

Wireless sensors are an automated solution to temperature monitoring and have several clear advantages over manual or wired solutions:

- They are easy to find, set up, and operate

- Relocating them is easy and inexpensive

- Cloud data storage prevents data loss in the case of system failures

- Users can access data from remote locations

How wireless temperature monitoring works

Temperature monitors are a part of the Internet-of-Things (IoT) network, making it easy to access important food storage temperature information whenever or wherever necessary.

What is IoT 🤔?

The Internet of Things (IoT) is the network of physical objects, such as your phone or laptop, connecting through software, sensors, or any other technology. These objects communicate information to each other and to the cloud.

With an increasing number of items existing in the IoT, experts estimate that more than 7 billion devices are connected today, with experts expecting this number to grow to 22 billion by 2025.

Continuous temperature monitoring systems may vary in terms of features, but a quality platform usually includes these three main components:

The sensor

This hardware component measures temperature, humidity, or both and transmits the data to a centralized hub. Each sensor uses a specific network, such as Ethernet, WiFi, BlueTooth, or LoRaWAN®. The sensor network is important to consider because signals like WiFi and Bluetooth are stronger in homes, whereas LoRaWAN® is a better fit for commercial use cases.

The hub

Hubs are data exchanges that provide easy sharing of information between devices. A hub connects information from the data-generating devices—in this case, the temperature sensors—with the cloud, where users can easily access it.

The software

The hub feeds data into software that interprets, analyzes, and displays the sensor data.

In the case of temperature monitoring, an operator can quickly take action when sudden, and unexpected temperature changes occur. The more customization options the software provides, the better. Having various options allows users to personalize alarms, factor in downtime from maintenance, and tailor their software to get the data they need most.

However, Bluetooth and WiFi signals are unreliable in noisy environments or those that have thick walls and metal-plated doors. Since most storage spaces and walk-in coolers are located at the back of facilities or in underground spaces, Bluetooth and WiFi devices may fail to monitor temperatures accurately in these areas.

How to select the best network type for your wireless sensors

Selecting the right network type is paramount to your sensor connectivity. Here are a few practical considerations about Bluetooth and WiFi systems:

- Microwaves, neighboring WiFi networks, refrigerators, fish tanks, and even Christmas lights can interfere with WiFi signals.

- A typical 2.4Ghz WiFi network covers only around 150 feet indoors and 800 outdoors—not that much for a restaurant facility.

- WiFi freezer temperature sensors may work better if you upgrade your WiFi network by adding a specific router for the monitored area. However, even this upgrade may not be enough to prevent signal loss due to secure metal doors. A technician must complete these upgrades, thus adding to the installation cost and making maintenance challenging for employees.

- These systems are dependent on reliable internet connections, which can cause problems in remote areas or on food trucks.

- Cloud storage subscriptions represent additional annual charges for the user.

LoRaWAN® wireless temperature monitoring

LoRa stands for “Long-range Radio,” and LoRaWAN® refers to the network that uses these radio signals. It’s a network system designed to provide power and range balance in communications. LoRaWAN® is becoming popular in environments where Bluetooth is not an option or WiFi is susceptible to interference. Specially designed to provide peak performance for communications and smart-device interoperations, LoRaWAN® uses less power and can run on a single set of batteries for years at a time.

This variety of wireless technology transmits data over long distances and through dense environments, so it’s ideal for the rigorous temperature monitoring procedures needed to ensure food quality.

At the same time, while Bluetooth has always struggled with security issues, LoRaWAN® developers have made authentication and encryption mandatory. This guarantees a more secure network. It can protect your restaurant from increasingly common threats, such as ransomware attacks, which increased 250% from 2016 to 2017.

This technology can also fight non-human threats. For example, in case of a power outage, these systems keep a complete record of temperatures during the outage, allowing you to assess any damage better.

GlacierGrid's temperature monitoring system

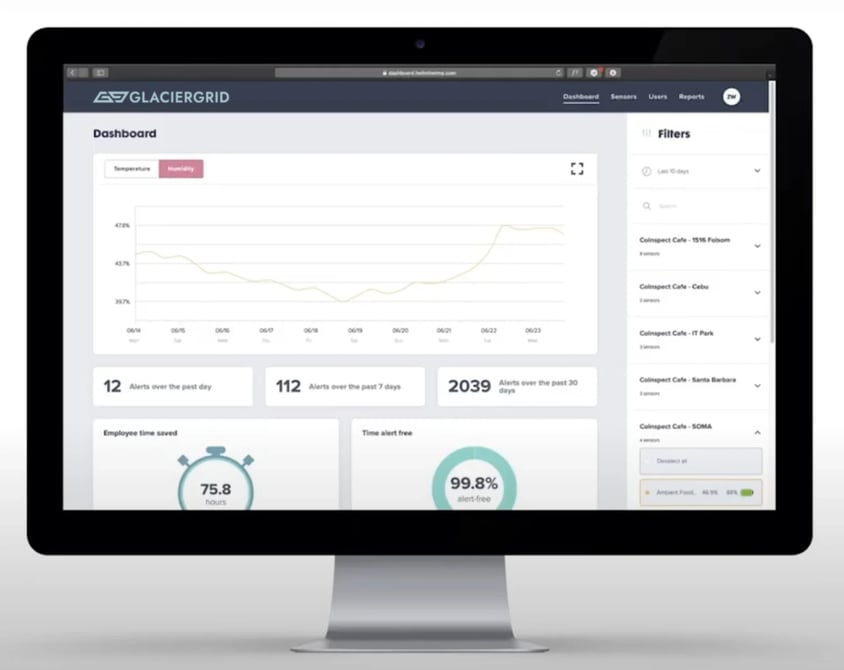

GlacierGrid's temperature monitoring and analytics platform exemplifies how LoRaWAN® technologies provide unparalleled connectivity within noisy environments, where WiFi and Bluetooth devices may struggle or fail. Our product suite integrates features developed specifically for the food industry:

Unparalleled Connectivity

- GlacierGrid interactive dashboard, mobile app, and SMS/email/phone notifications keep your staff continually informed. With all your data backed up digitally and easily accessible, you can quickly visualize records for internal or external auditing.

- With our user-friendly dashboard, you can undertake scheduled planning, food waste auditing, and health and safety inspections.

- During power outages, GlacierGrid uploads a complete record of temperatures as soon as the power comes back on.

- Smart alerts enable users to adjust temperature thresholds to prevent excessive notifications while automatically increasing or decreasing the temperature threshold one degree at a time.

1,200+ Foot Range

- GlacierGrid’s unique use of LoRaWAN® technology allows it to produce consistent readings, even in noisy urban environments or through thick walls. This reduces installation costs and provides safer use in multi-level facilities and even adjacent buildings.

- With a 1,200+ square foot range, LoRaWAN® technology allows seamless operation throughout all your units. If you are in a remote location, our system will still collect and log your data.

Scalability

We recognize that all restaurants, from large QSR chains to local diners, benefit from the advantages of LoRaWAN® temp sensors.

With GlacierGrid, there are no minimum order requirements; buy only what you need to protect your inventory. What’s more, if your business grows, you can expand your sensor network easily without high costs or complicated installation.

Continuous temperature monitoring in action

Temperature sensor technology is evolving and becoming more reliable each day, providing solutions to critical food safety and food waste issues in the food industry. For restauranteurs, the market offers many choices.

Operators need an effective temperature tracking technology customized to fit their individual needs and budget. Automated temperature sensors make your workflow smoother and your products safer for customers, which improves your bottom line.

Whether you are looking for relative humidity sensors, walk-in cooler temperature monitors, or freezer temperature sensors, be sure to choose a system that can take you to the next level of safety and productivity. Click below to see for yourself how GlacierGrid can help you rest easy while saving money.