The Cold Chain Paradox—Unhealthy Impact of Healthy Living

Modern life relies on the supply chain. The transport of goods and the accompanying services they enable are the cornerstone of international trade and the world economy.

Nowhere is the importance of the supply chain more crucial than in the shipping and storage of perishable items that rely on refrigeration.

This overall process of refrigeration-supported transport is also known as the cold supply chain, or simply—the cold chain.

However, there is a crack in our cold supply chain. One that takes the term “cruel irony” to a whole new level.

The state and dilemma of the global cold supply chain

As globalization increases and global supply chains modernize, the products that move through international trade and the cold chain have become more critical.

Notably, the rapid advancement of the global market, in addition to the economic progress of the third world, (particularly in South and East Asia), drastically changed what people eat and how they purchase industrial and agricultural commodities.

In other words, more and more people are relying on the modern cold supply chain due to the ever-growing effect of the climate crisis.

And in an ironic response, the current systems behind powering this cold chain continue to contribute further to the climate crisis.

This begs the question: how do we reach a compromise between our need for a healthy, comfortable lifestyle and that lifestyle’s negative effect on our environment?

The effect of economic development in the third world

Economic development in the Asia-Pacific (APAC) region and the emergence of the global middle class as part of the broader world economy both play a significant role in upgrading the cold commodity chain and the broader global supply chains.

This increased economic activity typically comes with a broader upgrading of consumer habits. With financial stability comes increased reliance on luxury goods and services and a restructuring of how buyers access them, according to some commodity chain analyses.

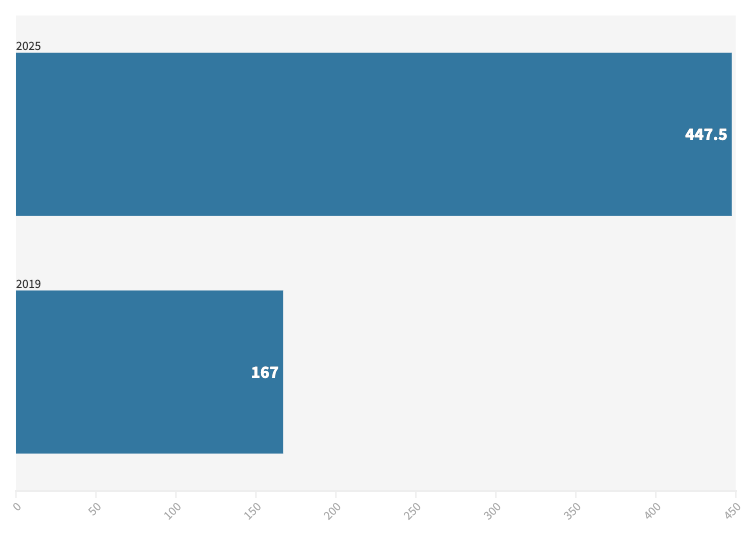

The expected growth in the value of the cold chain over six years (in Billions of dollars)

One of the most emblematic shifts has occurred in sourcing groceries and the raw materials used in the production process of finished commodities, like frozen food items.

Middle-class consumers in these regions are increasingly transitioning from a tradition of sourcing raw materials and food from local vendors, also known as “wet markets.”

In contrast, the “supermarket” model of economic activity is becoming more prevalent, increasing, according to some value chain analysis, by 7% a year.

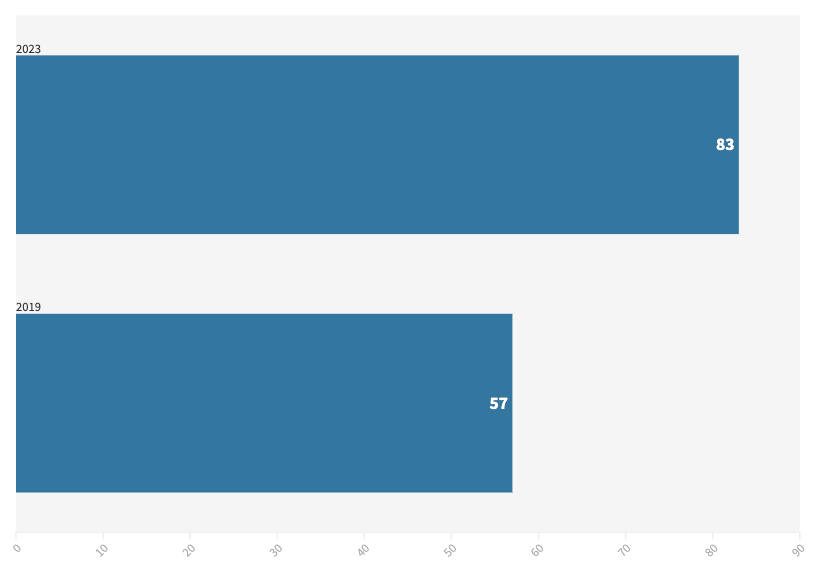

The expected growth in the value of the frozen food market in APAC over four years (In billions of dollars)

Given that the majority of the world’s population lives within the broader APAC region and that some commodity chain analysis projects the Asian middle class to grow 75% in the next ten years, reliance on the global commodity chain should increase in tandem.

Climate change and the global commodity chains

While supermarkets and global production have enabled the new middle class to enjoy healthier, fresher food consistently, this comes with an environmental price to pay.

What was once grown and transported locally must now be shipped through a global commodity chain and be constantly refrigerated at the optimal temperature range

In turn, the supply chain requires increased use of diesel fuel, refrigerants, and electricity to ensure quality and consistency.

Extrapolating the current model as it is in the west, the growth and consequences of the cold supply chain, or cold chain, becomes a paradox.

Items shipped through the cold chain lead to better outcomes and quality of life while intensifying the factors that made life more dangerous and less stable in the first place.

Consider this case study:

Cooling is more of a necessity when elevated temperatures are a constant rather than an anomaly. While cooling provides solutions to the problems posed by climate change, it’s also a significant contributor to those same problems.

According to some economists, cooling consumes nearly 20% of electricity worldwide and is responsible for over 10% of global greenhouse gas emissions in some global value chains.

Due to the consistently higher temperatures caused by power and cooling, those numbers should increase accordingly, creating a feedback loop where the solution is the problem.

The same principle applies to linkages within the cold supply chain:

The more reliant the world becomes on items shipped through the cold chain, the more the climate will be affected.

Improving supply chain management

Everyone deserves a safe, comfortable, and healthy existence. The difficulty comes from providing that comfort and convenience without intensifying the symptoms that created the climate crisis.

Solving this paradox requires better supply chain management. There are some short-term solutions to the cold supply chain’s climate problem with enhanced supply chain management techniques that we can consider though.

1. Cooling as a Service (CaaS)

Cooling as a Service is a commodity chain approach based on the concept of servitization.

By providing inexpensive short-term cold storage linkages in areas that lack start-up capital or infrastructure for industrial cooling, producers and consumers both benefit.

Local retailers reap higher returns for their agricultural commodities because cold storage allows them to preserve their products for much longer than they otherwise would—in turn, wasting less.

Furthermore, because the operator stored the item correctly, the quality and safety of the items would also improve.

The added benefit of CaaS is that it preserves traditional supply chains, production systems, and production processes.

Instead of restructuring the production processes used by local farmers and wet markets for centuries in favor of transnational grocery stores, CaaS maintains the historic sourcing methods of retailers while optimizing them.

2. Natural refrigerants and the global commodity chain

While cooling systems, such as refrigeration, accounts for 10% of global electricity use. This, alongside heating, ventilation, and air conditioning (HVAC) systems represent 4% of global emissions.

Gas leakage is common in all HVAC systems used in the world economy. This is especially true for older systems, due to the machine’s hardware deterioration over time.

Since the mid-20th century, real-world manufacturers throughout the global economy have relied on various gases that, while non-flammable, have massive global warming potential.

However, in a nod to the early days of refrigeration, retailers and transnational logistics providers are turning to natural refrigerants, such as CO2 and Ammonia, to improve their carbon footprint.

New compression technology has allowed engineers to create systems that utilize these (relatively) more environmentally friendly gasses without sacrificing safety.

3. Upgrading to real-world wireless monitoring solutions in production networks

Implementing natural refrigeration is infrastructure-intensive and often financially inaccessible for small to medium-sized businesses.

Wireless monitoring solutions offer a stop-gap by detecting refrigerant leakage and excess electricity use. This early detection system opens proactive opportunities for improved efficiency and reduced food waste.

Remote temperature monitoring systems function as sensors or nodes that operators install within cold storage equipment to measure temperature, humidity, or any other designated metric.

To understand the potential positive impact of remote monitoring, we must first understand its methodology:

- When a component of a refrigeration system breaks down, the unit will start warming up instead of cooling.

- A monitor installed in that specific refrigerator will then alert operators to that equipment’s potential breakdown.

- Operators now have ample time to take proactive measures, rectifying the issue before further excess electricity is spent or any refrigerants leak.

Listen to our CEO talk about his company's user-friendly and reliable take of this technology:

Why a Smart Cold Chain is Vital for a Warming Planet—Manik Suri on Techonomy Climate 2022

Hope for improving globalization and the supply chain

The problems presented by cooling-related emissions are numerous. Due to various degrees of industrialization throughout the global economy, alleviating them will require a multi-pronged approach.

While the innovations listed above are a healthy step forward, they represent just the beginning of what is necessary to make the desired positive impact.

We must invest more into supply chain research as soon as possible. More accessible and cost-efficient solutions must be created to encourage international corporations to shift towards greener operations.

At the end of the day, reforming the cold supply chain is a must to finally break the paradox.