Wireless Humidity Sensors in Food Manufacturing

Humidity is the amount of moisture present within a given environment, and it negatively contributes to the longevity and safety of perishable and frozen food items.

This article will dive deeper into how humidity management affects both perishable and frozen food items and how humidity monitoring equipment can help food manufacturers manage their facilities.

The true cost of humidity and condensation buildup

Humidity presents specific challenges to food manufacturing, including:

High variability based on product and transport conditions

Perishable goods require different environments for different items. In general, fruits and meats prefer drier climates, while vegetables prefer more humid environments. Food manufacturers aim to provide consistent environmental conditions, but unsealed refrigerator doors, ice buildup on equipment, and varying production temperatures create challenges in maintaining uniform humidity levels.

Quality assurance and product loss

Fungi and bacteria thrive in humid conditions, creating opportunities for quality assurance incidents and product loss.

Freezer energy consumption

Humidity drives ice build-up in equipment, increasing energy costs through excess defrosting cycles. Product loss due to spoilage, bacteria, and fungi is one of the obvious problems when calculating the real cost of condensation, but the high cost of energy should also be considered. Excess condensation and moisture buildup can be a sign that a refrigerator or freezer has a much higher energy usage than is necessary, running longer or harder than it would under ideal conditions. Additionally, an overworked fan motor and compressor will lead to more frequent appliance repairs. These repairs can get quite expensive if an appliance is no longer under warranty.

The danger of excess moisture to perishables

Poor humidity management creates excess moisture which affects perishables by encouraging the growth of fungi and bacteria. Fungi usually takes on the appearance of green, blue, or white mold on perishables. When operators notice fungal growth, the contaminated product must be thrown away.

Unlike fungi, bacteria are invisible to the eye, so microbiological testing must be conducted on products to identify their presence. Manufacturers and food inspectors rely on samples to perform these tests. Sampling is an effective method to ensure food safety, but given the manufacturing scale, there is always the risk that contaminated products may go unnoticed.

One particular bacteria, Salmonella, thrives in food stored in humidity-intensive environments. Salmonella is one of the leading causes of foodborne illness in the United States, causing 1.35 million infections every year.

The repercussions of a Salmonella outbreak are expensive, with the average recall costing about $10 million. While QA checks won’t always reveal Salmonella’s presence, monitoring storage for conditions that increase its likelihood allows manufacturers to re-inspect potentially spoiled items before it’s too late.

Below are some common causes of excess moisture in coolers that can be addressed during regular troubleshooting sessions.

Proper door seal

Left open, a refrigerator door allows warm air to mix with the cold air of a refrigerator or freezer, but this problem can extend beyond whether or not the freezer door is shut. A leaky gasket can allow outside air to seep into the cooler. A proper door gasket is a must.

The Local Climate

Ambient humidity can also affect the interior of a cooler. If the cooler or freezer is in a climate with naturally high humidity, fighting moisture buildup can be even more of a challenge.

Moisture from the food items

Fresh produce, while bringing better flavors, also brings added moisture problems. The extra water within these ingredients will evaporate out of the produce over time, creating condensation and leading to faster spoilage.

Overfilled cooler

An overloaded cooler can also contribute to excessive moisture. If products are tightly packed in from the refrigerator door to the back wall, it will hamper the airflow of the freezer compartment putting an undue strain on the fan motor as it struggles to push cold air past the obstacles.

The effect excess moisture has on frozen foods

Humidity also affects frozen food quality and facilities. Product quality is affected when an excess of moisture is present in processing. At warmer temperatures, food is more porous and absorbs moisture. When the product falls below the freezing point, ice crystals form from the absorbed moisture, negatively affecting the product’s taste and texture. Ultimately, customers can taste how humidity affects frozen food. “It tends to be on the chewy or tough side,” said Bob Schrader, a consultant for food humidity solution, MicroGold.

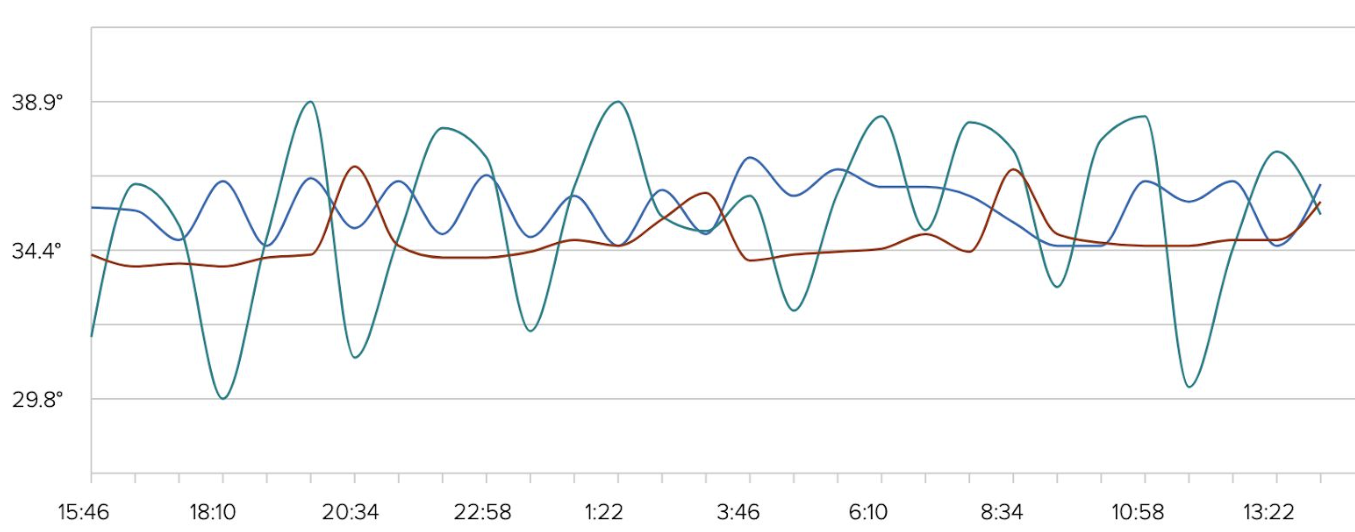

There are two common problems present in the freezer compartment that both have to do with excess moisture but in different ways. There is ice buildup, which can be caused by liquid spills, leaky water lines or water accumulation in the defrost drain or the drain pan, causing slick, dense layers of ice to form. Then there is frost or rime ice buildup. Frost and rime ice are caused by the rapid freezing of water vapor present in the warmer room air, often forming on the evaporator coil which operates at -20 degrees F. Poor humidity management often causes these challenges in frozen facilities. To combat ice build-up, operators rely on freezer defrost cycles, which generate power surges that drive up electricity costs, even in energy-saving appliances. The chart below illustrates the occurrence of defrosting cycles over 24 hours from a GlacierGrid customer in food manufacturing:

GlacierGrid’s wireless humidity sensors

To verify optimal storage conditions, food manufacturing staff should perform environmental checks every hour. However, traditional thermometers and thermostats don’t always give accurate readings, and staff can’t monitor facilities after hours. GlacierGrid’s wireless humidity sensors provide automated, NIST-certified reporting and alerts for cold storage conditions. Our customers, such as NOW Foods, use GlacierGrid’s wireless humidity sensors in the following ways:

- GlacierGrid’s alert system prompts staff to perform thorough area inspections when environmental conditions start to vary, allowing them to identify factors like moist or cool air seeping through doors and other entryways.

- A spike in humidity often indicates a cooler breakdown. When this happens, GlacierGrid’s alerts allow staff to relocate inventory to alternate storage areas. Additionally, these alerts provide insights into whether inventory was stored in conditions that promoted bacterial growth. In this situation, further microbiological testing can be performed before manufacturers distribute spoiled food.

With GlacierGrid’s automated humidity reports from freezers, operators can decrease the frequency of energy-intensive defrost cycles.

Interested in working with GlacierGrid?

To see how GlacierGrid can help increase the quality and longevity of your frozen inventory, click below to buy sensors online.