How to Identify and Prevent Time-Temperature Abuse

Temperature control is crucial to safeguarding your inventory, protecting your profits, and preventing foodborne illnesses in your restaurant or food service establishment.

Temperature excursions, or changes in your food storage temperatures, happen all the time in restaurants due to equipment malfunction and user error. And when these temperature changes go unnoticed, the food affected experiences what’s called time-temperature abuse.

Read on to learn what you can do to keep food out of the danger zone, and prevent time-temperature abuse. Learn how new tools and equipment make it easier than ever to detect the need for corrective action before it’s too late.

What is time-temperature abuse?

Along with cross-contamination, time-temperature abuse is one of the most common food safety violations, and primary causes of foodborne illnesses.

Time-temperature abuse happens when food isn’t stored at the correct temperatures.

Servsafe identifies the following safe temperature guidelines for food storage:

- Cold foods must be stored at an internal temperature of 41°F or lower.

- Hot foods must be stored at 135°F or higher.

- Frozen food items must be stored frozen.

- Storage should be well-ventilated with open shelving and a visible thermometer, accurate to plus or minus 3 degrees Fahrenheit.

According to the Certified Food Safe Professional (CFSP) Credential, there are three ways that time-temperature abuse occurs:

- Food is stored or held at temperatures inside the danger zone (41-135° F) for longer than 4 hours. For reference, room temperature is considered to be between 68° and 74° F.

- Food handlers not following cooking temperature/time recommendations to ensure hot foods reach the minimum internal temperature during the cooking process.

- Food handlers cooling and reheating foods incorrectly.

Why is continuous temperature monitoring important for food?

All food is at risk of spoilage due to changes in temperature during production, storage, preparation, and serving. Even sealed, shelf-stable food, like canned goods, can experience time-temperature abuse if exposed to extreme high or low temperatures.

Some types of food are especially vulnerable to spoilage. This class of food is referred to as Time/Temperature Control for Safety (TCS) foods. These high-risk food products include dairy products, meat, and seafood. Click here for a more complete list.

Closely monitoring TCS foods plays a major role in protecting your restaurant’s profits.

85% of restaurant food waste events occur due to poor temperature control, causing an average profit loss of 28-35%.

Frequent monitoring is also important for your customers’ safety.

Foodborne pathogens like Salmonella grow rapidly in the 40°F-140°F temperature range, doubling in number in as little as 20 minutes. This is why it is important that cold-holding equipment keeps foods at temperatures below 40°F, and hot-holding equipment can maintain a temperature above 140°F.

Although food may look and smell normal, it may not always be safe to eat. It’s important to have clear and frequent food temperature logs to make sure the food you’re serving to your customers has been stored at the proper temperature and won’t make them sick.

Tools and Methods to help you prevent time-temperature abuse

In 2010, Congress passed the Food Standards Modernization Act (FSMA) requiring all food manufacturing facilities to have “adequate temperature controls”.

Today, manual checks and handwritten logs are the most common temperature controls used to monitor changes in food storage units.

These checks are typically done every 2 hours to look for any signs of temperature excursions in your storage equipment, allowing enough time for corrective action before you hit the 4-hour limit set by ServSafe.

But manual temperature controls can be time-consuming, and they’re often overlooked during busy shifts. Because time constraints are so common in the food industry, not only do manual inspections run the risk of misreporting, but they create situations where faulty equipment, like a broken freezer condenser, can be overlooked well into the thawing process. On a good day, manual inspections are inefficient. On a bad day, they are downright dangerous.

Smart thermometers, as part of a remote temperature monitoring system, are a more efficient way to track temperature excursions and avoid time-temperature abuse events.

GlacierGrid is a great option for foodservice providers that automates this monitoring process, allowing your staff to focus on their other tasks while still ensuring you keep food safe for your consumers.

How much money can I save using GlacierGrid?

With this automated system, sensors take consistent temperature measurements in your food storage spaces and save each data point to the cloud.

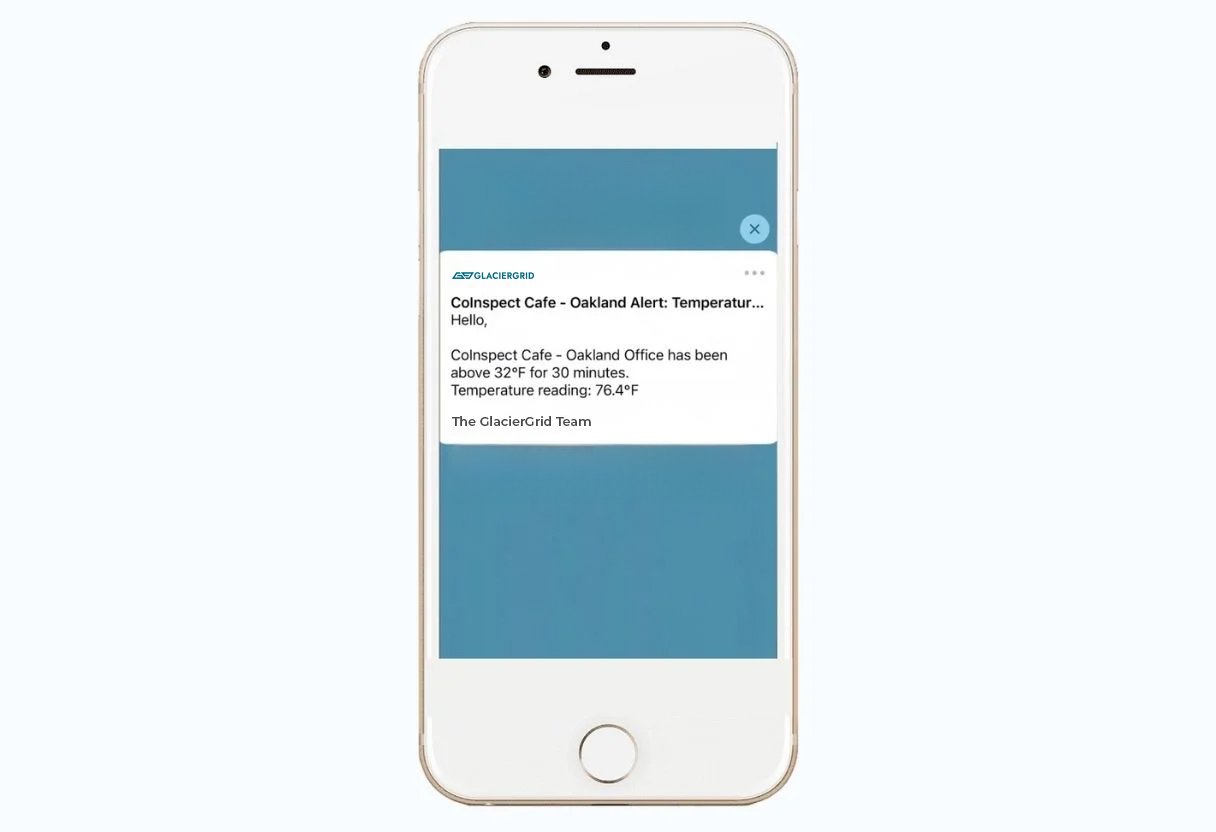

If your storage temperatures read inside the temperature danger zone, GlacierGrid will alert you and your team through SMS, phone call, push notification, or email so you can respond to the temperature excursion within minutes, before pathogens have a chance to grow.

The potential savings will vary depending on your business, but typical savings for GlacierGrid users add up to $15,000 per location. Check out how this McDonald’s franchisee saved thousands using this system.

Interested in seeing how much money GlacierGrid can save you? Click here to learn more.